-

+91 98984 89248

- info@technopowereng.com

- Odhav

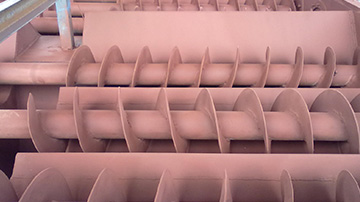

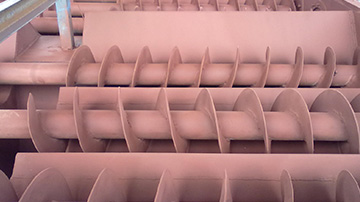

Screw Conveyor

Tubular Screw Conveyor

Flexible Screw Conveyors

Spiral Classifiers

Tubular Screw Conveyor

Product Description

The modular TU Tubular Screw Conveyor and Feeder system is highly versatile offering a variety of standard solutions for handling of powdery or granular materials. Different models of conveyors or feeders are available in applications such as concrete production (for fly-ash, filler dust, silica fume), premixed building materials (dry plasters, sand, cement, additives), glass processing (calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), and many others.

Features:

- 7 outside tube diameters

- Outside tube complete with welded end flanges, one inlet, one outlet, inspection hatch beneath inlet and each intermediate hanger bearing

- Helical screw flighting welded on center pipe

- Powder-coated

- End bearing assemblies complete with self-adjusting shaft seal

- Splined shaft couplings

- Lifting eyelets on each tube section

- Various types of screw flighting

- Compact design and overall dimensions

- Limited number of components and spare parts

- Maintenance-free versions available

Benefits

- Small diameter, great efficiency, high throughput rates

- Modular design offering great variety of options suitable for numerous applications

- Easy installation

- Durable

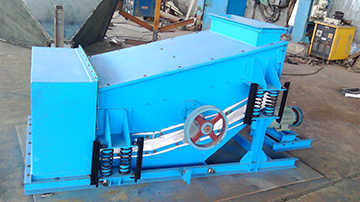

Flexible Screw Conveyors

Product Description

Move virtually any bulk material

Free-flowing and non-free-flowing materials and blends

Techno Power flexible screw conveyors (also known as helix conveyors, screw conveyors, spiral conveyors and auger conveyors) offer efficiency and versatility, conveying bulk materials ranging from large pellets to sub-micron powders—both free-flowing and non-free-flowing—with no separation of blended products.

Mobile and custom configurations

All Techno Power flexible screw conveyors are available on caster-mounted frames with conveyor support masts for in-plant mobility, reducing the need for multiple stationary units.

Both mobile and stationary units are readily customized using interchangeable screws, conveyor tubes, drive motors, hoppers, flow-promotion devices, sensors, controllers, and other components to satisfy the most diverse and demanding end-use requirements.

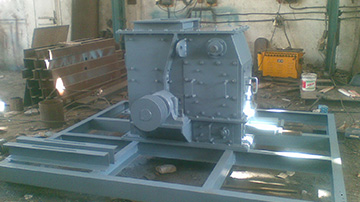

Spiral Classifiers

Product Description

The Spiral Classifier is available with spiral diameters up to 120″. These classifiers are built in three models with 100%, 125% and 150% spiral submergence with straight side tanks or modified flared or full flared tanks. All sizes and models are available with single-, double- or triple-pitch spirals.

The Spiral Classifier offers the greatest sand raking capacity of any classifier available.

The tank is heavy plate with strong structural base. The extra heavy shaft has an improved submerged bearing. The greatest improvements, however, are found in the drive-unit which has been strengthened and improved over all other classifiers. A specially designed classifier reducer eliminates the “over – hang” or cantilevered load normally found where the reducer shaft carries the pinion. The Classifier Reducer has an outboard bearing integral with the reducer base which provides positive alignment of the bevel gears.

The gears themselves are greatly improved as they are cast from metal patterns which have cut teeth. The accuracy of the patterns and the quality gear castings result in a cast-tooth gear of cut-tooth quality. The gears mesh smoothly, have greatly increased capacity and are noticeably more quiet than other spiral classifiers.

Spiral Classifiers are available in sizes up to 120″ diameter, three tank styles, single, double and triple pitch spirals, three degrees of spiral submergence —flexibility to provide a unit built for your job. Write for detailed recommendation on the correct size and type of Spiral Classifier to do your job economically and profitably.

Our Products

Previous

Next

These are not mere words at Techno Power but our guiding principles. Coupled together with unmatched business ethics and uncompromising quality control

Products

Belt Conveyor

Screw Conveyor

Bucket Elevator

Drag Chain Conveyor

View More Products

Projects

Coal Handling Plant

Urea Coating System With Neem Oil

Salt Washery Plant

Drag Chain Conveyor

View More Projects

Contact Details

- Plot No.9 Alpam Prerna Industrial Park, B/h. Swastik Business Park Pirana Gate, Sardar Patel Ring Rd, Ode, Gujarat 382427

- Sales@technopowereng.com

- +91 – 98984 89248

@Copyright 2022 Techno Power | Powered by V3MARK